Fischer RCS Carbonlite ski technology review

Thu, Dec 4, 2008 - By Fischer

The RCS Carbonlite ski is the most technologically advanced ski produced by Fischer to date. For decades, Fischer has been using carbon in the production of composite materials. Because of this, Fischer has obtained extensive knowledge and experience in using these strong and lightweight materials to design and build our skis. Combining this knowledge of carbon-composite material design with our proven Air Core technology, a state of the art Computer Flex Control pairing system and a industry-leading base preparation process places the RCS Carbonlite ski at the summit of racing performance skis in the world today. Whether you are a world-class racer or a weekend warrior, the RCS Carbonlite is the ski that will help you reach your goals.

Features:

- Air Core Carbonlite

- Carbon Tip and Tail

- Digital Tuned Grinding

- Prewaxed

- CFC

- Speed Tip and Tail

- World Cup Cold and Plus base

Features:

- Air Core Carbonlite

- Carbon Tip and Tail

- Diamond Tuned Grinding

- Prewaxed

- CFC

- Speed Tip and Tail

- World Cup Cold and Plus base

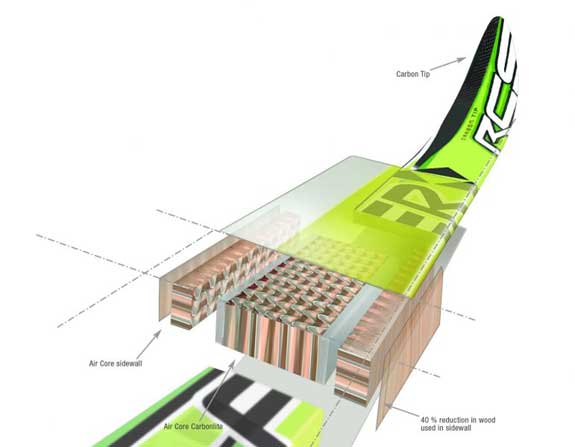

The construction of our Carbonlite Skate and Classic ski begins with our Air Core technology. Using our newly developed Bi-Directional Air Core and combining this new core with our Fischer Carbon Fibre, Fischer is now able to construct the Carbonlite ski around a lighter core material, reducing the thickness and weight of the sidewall, while retaining the integrity and responsive characteristics inherent in all Fischer racing skis.

Carbonlite Bi-Directional Core

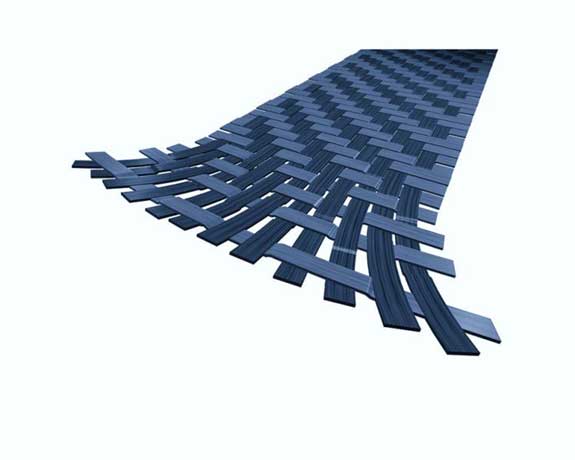

Fischer Carbon Fibre

Through Fischer’s industry leading position in composite materials, the Carbonlite ski uses the newly developed, multi-axial T300 1K Carbon within the tip and tail of the ski. The use of this new carbon fibre works in conjunction with the bi-directional Air Core to further reduce the weight of the ski.

Not only does the Carbon Tip and Tail cut down on the overall weight of the ski, it also reduces the weight of the ski in the most important areas, the tip and the tail.

Carbon Tip and Tail

This minimizes the Swing Weight of the ski, which results in the lowest possible mass inertia available in any ski on the market, providing more speed, improved response time and increased efficiency of movement.

Minimal Swing Weight

The Carbonlite ski is shaped with an Arrow Shaped Side Cut. In the skating technique, this side cut improves the performance and dynamic action of the ski, permitting the ski to glide flatter and longer.

Every pair of Carbonlite skis is matched using Fischer’s new Computer Flex Control pairing system. This automated pairing process measures the camber curve of each ski, taking a measurement every 2mm along the length of the ski from tip to tail. This process guarantees the lowest possible tolerances, providing a perfectly matched pair of skis with the best possible glide and kick performance available.

Computer Flex Control

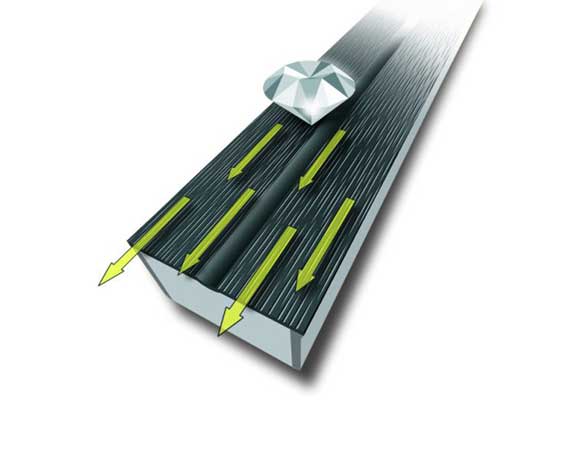

Fischer’s world class Diamond Tuned Grinding process provides each Carbonlite ski with the highest quality base structure pattern. This grinding process utilizes state of the art ski grinding machines, different diamond types and structure patterns for unique snow conditions. The Diamond Tuned Grinding Cold is Fischer’s Cold structure, which is used on all Carbonlite Classic and Skate Cold skis. The Cold structure, created by a synthetic diamond, is a fine, smooth and shallow structure designed for cold and dry snow conditions, ranging from 23 degrees Fahrenheit and colder. The Diamond Tuned Grinding Plus iis Fischer’s Plus structure, which is used on all Carbonlite Classic and Skate Plus skis. The Plus structure, created by a natural diamond, is a deeper and coarser structure designed for warmer and higher humidity snow conditions, ranging from 23 degrees Fahrenheit and warmer.

Diamond Tuned Grinding Cold

Diamond Tuned Grinding Plus

Prewaxing is the last step in the production process of a Fischer Carbonlite ski. After the grinding process, each ski is waxed at the factory using an infrared process, which allows the wax to fully penetrate into the base and protects the ski base from oxidation and contamination during the shipping process. Every Carbonlite Cold ski is waxed with Swix LF7 and every Carbonlite Plus ski is waxed with Swix LF8, making the skis as fast as possible directly off the rack.

Prewaxing on Fischer Carbonlite skis

Local ski shops carrying Fischer skis (they also do mail order):

- Cross Country Ski Shop, Grayling, MI

- Cross Country Ski Headquarters, Higgins Lake, MI