Solda introduces non-fluoro ski waxes

Fri, Feb 28, 2020 - By Bert Hinkley

In 1934 Gino Solda launched a small company in Italy focused on the production of high quality ski wax. Solda waxes were produced, sold and used all over Central Europe using formulas that were primarily based on hydrocarbon paraffins with synthetic additives that enhanced the glide of skis on various snow conditions. In the mid 1980s Manlio Solda, a skier, wax maker and chemical engineer, discovered a process to combine fluorine with hydrocarbon waxes which made the waxes extremely hydrophobic ( reduced water adhesion ) and improved glide, especially in wet snow conditions. Other wax companies followed this lead and fluorocarbon compounds became common in ski wax applications, especially as additives applied for racing. It was a time when we did not know what we did not know.

We now know that Per-Fluorinated compounds with greater than 6 carbon/fluorine bonds on the molecular chain, have proven to be harmful to the respiratory systems of wax techs who were applying them to skis without the use of organic filtration respirators. There is also some evidence that fluorinated compounds of greater than C6 do not break down in the environment and may be hazardous to water quality, soil health and animal health. The collection of these data are ongoing.

With this awareness, Solda began to reformulate their waxes and in 2016 began to sell products with fluorocarbon compounds of C6 or less. These new formulas conformed to the 2020 European Union regulations.

With all this in mind and with an eye on the future, in 2008 Solda wax began to experiment with non-fluorinated additives that would both not be harmful to wax technicians or to the environment. The chemists working with Solda became aware of an industrial lubricant that is biodegradable, non-toxic and sustainable. This German made product was initially developed for industrial applications where durability of the lubricant in extreme conditions was desired. The new Solda wax with H-Lubrix additive is called the New Era Line.

The most familiar form of the New Era Line is the Superglide that is a blend of hydrocarbon waxes and H-Lubrix. It comes in three snow temperature ranges with Yellow for 0ºC/-1ºC (testing has shown it will run well down to -3ºC snow), Red for -2ºC/-10ºC and Green for -10ºC/-20ºC. While it is recommended that this be applied with an iron for greater durability, we have had success dry rubbing the wax on the ski base and using a rotocork and nylon polishing brush to finish it. This method was used by some coaches for recent races in the PNSA U14 classes where fluorinated waxes are not allowed. The skis ran well. The H-Lubrix additive softens the paraffin block and for this reason, in cold snow it is recommended that a base of Solda S30 be ironed on first.

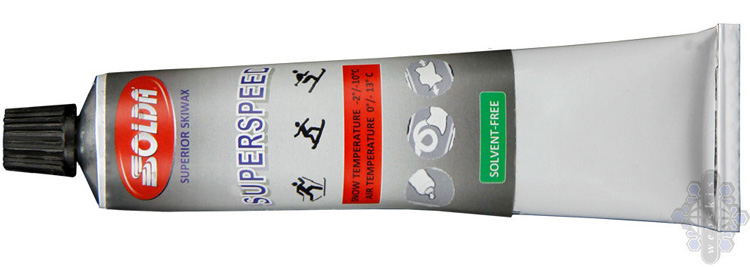

Superspeed paste is an alternative to the Superglide paraffin. The paste is applied with a sponge, soft cloth or fiberlene and spread on the ski base. After setting for 5-10 minutes polish it with a clean, soft cloth. For greater durability it can be ironed with a piece of fiberlene between the iron and the base and then finish with brushing using a soft nylon polishing brush.

Superglide waxes have been tested on both natural snow and even man-made snow in the Torsby Ski Tunnel in Norway. I had some samples that I tested in April of 2019 at Mt Bachelor, Oregon. The Super Glide waxes have tested favorably against both LF fluorinated and non-fluorinated waxes. Reports from wax testers in Sweden, Norway and Germany have been very positive and the Superglide is being used in the youth classes where fluorinated waxes are banned.

These waxes are now available at Webskis.com. We have recently received samples of new, non-fluorinated powder additives and as soon as conditions are good we will be testing those new top coats. Stay tuned as we learn more about these new products.