Making a better rollerski pole tip (or How I hacked the Jenex VP-RSTD10 ferrule)

Sun, Oct 21, 2018 - By Frank Rynalski

Thought I would share this rollerski pole ferrule "tip" (pun intended!) with my fellow rollerskiers out there. If you do a lot of rollerskiing like I do, or have done repetitive arm movements over the years like I have as a mechanic, you may be experiencing some tennis elbow / tendinitis. Well I found a solution that remarkably cuts the shock / impact of the pole plants slamming into the pavement.

I knew for some time that shock absorbing tips were available from several different suppliers (Excel and V2) but I never considered them due to less than stellar reports from others who had used them. It wasn't until I needed some new rollerski ferrules that I decided to try the " suspension " version only because the shop didn't have any of the regular V2 ferrules that I normally use in stock. I bought Jenex's VP-RSTD10 Second Generation shock absorbing rollerski tips (ferrules) instead.

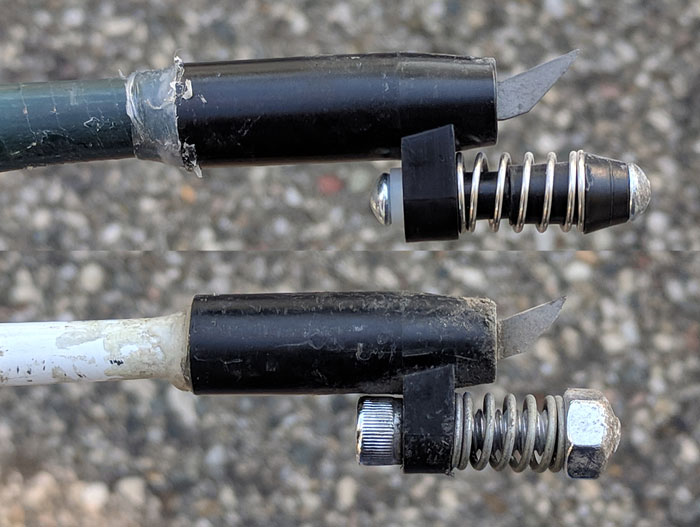

Stock Jenex VP-RSTD10 Second Generation shock absorbing rollerski tips (ferrules), pre-modification.

Review of the Jenex VP-RSTD10

I installed the new suspension tips and was anxious to try them out. To be honest, I really didn't like the "feel" that the new tips had, I guess kind of an unconnected feeling is how I would describe it. Well I told myself, "Give it time you'll get used to it". Well it didn't take much time because I destroyed one of the spring / plunger tips and I don't attribute brute strength to it's demise!

On the bright side the remainder of the tip was in fine shape, just the plunger fatigued and a tweaked spring.

By this time I had received a pair of the non-suspension tips that were on order and promptly installed them. Upon my next rollerski outing I could not stand the impact of the poles with the suspension-less ferrules. Yes, I had gotten used to the suspension tips so much that I HAD to have them back. One problem: They were not reliable, with a short lifespan!!!

Improving on the Jenex VP-RSTD10 design

So I was out to improve an already promising pole tip design. The main cause of my tip failure appeared to be the plunger / shaft which was bending and not tracking properly back into position (see picture of bent original and modified fix). I went down to my local Menards with my broken tip and found a 1/4-20 x 2 chrome plated socket head cap screw (chrome for smoother operation, went with 2 inch length only because that had a longer smooth shoulder to ride on rather than rough threads which the shorter cap screws had.). Next I matched up the spring as close to the original, which was a bit stiffer and longer, which doesn't seem to have a negative effect on operation (in fact I preferred the bit stiffer feel). Next I got some chrome plated 1/4-20 nylon lock nuts. All you need to do now is assemble just like original with said parts, tighten locking nut to attain same length as original spring plunger, approx. 9mm. past pole spike, and grind off protruding cap screw until flush with nut.

Original Jenex ferrule on top; modified, beefed up ferrule on the bottom. Metal shaft (instead of plastic), stiffer and stronger spring.

I have skied most of early summer and fall with no failures or problems and with less impact to my chronic tennis elbow, which has plagued me for years. Another plus with this pole tip, you're less likely to have your pole get stuck in pavement cracks and rip your shoulder / arm out of it's socket, since there's theoretically a larger poling platform.

The failed original plastic piston is on the left. A nice strong metal socket head cap screw replaces it.

My suggestion if you want to try this type pole tip is ski on it until it fails (if indeed it does fail). And at that point do the modification, I think you will be happy, especially if you battle with any kind of tendonitis issues.

Second comparison of the original Jenex ferrule (left) with my modified ferrule (right).

Here's a breakdown of the parts I used. I purchased the cap screw, spring, nuts from Menards but I'm sure your local well-stocked hardware would also have the needed parts:

- Suspension rollerski tip - VP-RSTD10 (second generation) V2 Jenex (XCHQ also stocks them)

- Handi-Pack, part # 87147 1/4-20 X 2 socket head cap screw

- Handi-Pack, part # 88261 13/32 X 1 compression spring

- Handi-Pack, part # 87028 1/4-20 nylon insert lock nut

This fix will greatly improve the stock Jenex VP-RSTD10 Second Generation shock absorbing rollerski tips. You can buy the Jenex ferrules from the Cross Country Ski Headquarters in Roscommon, Michigan.

When the pole hits the pavement, the spring-loaded metal piston absorbs some of the impact.

As the screw shaft wears from hitting the pavement, screw the nylon insert lock nut further up the shaft to reveal more screw.