Star Digital Iron Review

Digital Waxing Irons, Part 3

Thu, Feb 1, 2007 - By Zachary Caldwell

So, I called Len Johnson who is the US Star distributor. He had just received 4 of the new digital irons in a 110 volt configuration, and he sent me one (the one pictured) to test. Since I have considered the new Swix digital iron to be the standard of excellence in the industry, I'll make all my comparisons directly to that iron.

The Star iron has an 800 watt heating element (compared to 550 watt for the Swix). This means that it heats-up faster, and has to work less hard to maintain the desired temperature. The Swix iron has a microprocessor that controls the temperature. The Star iron has two microprocessors, each of which sample the temperature and parcel-out current 25 times per second.

Star is a family company, and one of the brothers involved is an electrical engineer. This iron is the product of a three-year development process. The electronics are spec'd out to suppliers, and the irons are assembled at the Star factory in Asiago. Pretty much all other irons on the market (including the Swix digital) are produced by one of several producers in the Czech Republic or in China.

The thought that has gone into designing and programming this iron is impressive. The folks at Star have been working with thick aluminum base plates all along, and have a good understanding of the thermodynamics at work. They have programmed the iron to overshoot the target temperature initially - the digital display blinks to tell you that it is still working on target temperature. Then, as the heating element cools the heat spreads evenly throughout the 10mm base plate, and the digital display stops blinking once the target temperature range is reached. Once the iron is up to temperature it can be maintained with short heating pulses, and there's no concern with the heat being uneven on the base.

One very reassuring feature of this iron is that the digital read-out displays the actual temperature that the internal probes are measuring. The Swix iron displays the actual temperature while the iron is heating up, but once it has reached target temperature it only displays that target temperature, regardless of the actual temperature.

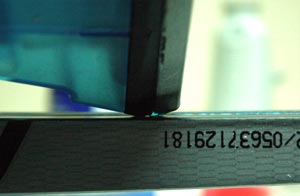

So that's the run-down of the design specifics - but how does the thing work? In short - wonderfully. The base plate has a rounded bevel on all four sides and the iron spreads wax incredibly easily regardless of which way you run it down the base. The space between the plastic body of the iron and the aluminum plate has been covered with some sort of heat resistant plastic (the black section you can see in the photos to the right). There is a new EU regulation which does not allow a design that can let molten wax behind the base plate where it can ignite and cause fires (not that I've ever seen that happen!). But the serendipitous result of this (or maybe it was by design) is that the black plastic section sticks out a few mm beyond the base plate. That means you can rest it right on the ski base and drip a solid bead of molten wax onto the base without dragging a 150degree piece of metal along your ski. I've always applied wax this way in any case, but it takes a huge amount of practice and an extremely light hand to avoid leaving a small trail of burned base behind. This iron makes it much easier to work like a pro. You can work quickly, with just the right amount of wax, and it will spread evenly on the ski in one slow pass from tip to tail. I tried to illustrate this with the pictures below.

So that's the run-down of the design specifics - but how does the thing work? In short - wonderfully. The base plate has a rounded bevel on all four sides and the iron spreads wax incredibly easily regardless of which way you run it down the base. The space between the plastic body of the iron and the aluminum plate has been covered with some sort of heat resistant plastic (the black section you can see in the photos to the right). There is a new EU regulation which does not allow a design that can let molten wax behind the base plate where it can ignite and cause fires (not that I've ever seen that happen!). But the serendipitous result of this (or maybe it was by design) is that the black plastic section sticks out a few mm beyond the base plate. That means you can rest it right on the ski base and drip a solid bead of molten wax onto the base without dragging a 150degree piece of metal along your ski. I've always applied wax this way in any case, but it takes a huge amount of practice and an extremely light hand to avoid leaving a small trail of burned base behind. This iron makes it much easier to work like a pro. You can work quickly, with just the right amount of wax, and it will spread evenly on the ski in one slow pass from tip to tail. I tried to illustrate this with the pictures below.

|

|

Once I had both the Swix and Star digital irons up and running in the shop I ran a test to see how they perform against each-other. I set each iron to 150 degrees C. Once an iron was up to target temperature I used an external thermocouple probe on my digital thermometer to test the actual temperature at the surface of the base. Both irons were about the same temperature - a little above the target temp. Once I had that starting temperature, I immediately dripped some Toko WorldLoppet Blue in a thin bead on each side of the groove, ironed from tip to tail once to smooth the wax, and then ironed from tip to tail again to heat the wax into the ski. Then, I immediately unplugged the iron and checked the temperature of the base of the iron again. The Swix iron had lost 10 degrees C from its starting temp and was 8 degrees below target and the Star iron had lost 4 degrees C and was 2 degree below target. I wouldn't take those absolute numbers to the bank because my thermocouple probe isn't designed for instantaneous readings of surfaces. But I would say that the relative difference is about right.

I my previous review of the Swix digital iron I stated that the temperature doesn't vary by more than a couple degrees. That was certainly my impression - based on the fact that the digital display NEVER varies, and the iron performs so much better than other irons that I've used. So I'm a little chagrinned to find that much variation after simply putting on a layer of cold paraffin. However, I'll stand-by my review of the Swix iron. It's a great tool. The Star iron is, in my opinion, even better.

After running these tests and working with the iron a bit more I called Len Johnson back. Four irons isn't terribly many. He had already called Star to enquire about additional irons, and they didn't have any 110 volt models on hand. There aren't many 110 volt markets in the world - pretty much just the North America and Japan. At our request they've initiated another production run and the irons should be in this country during the first week of December.

According to Lars, Star has made this iron as a labor of love. They have invested far too much money in the development of the iron to hope to reclaim the investment quickly or with great profit margins. Eventually they'll have to sell this iron to other companies with different branding (they've already been doing this with other models). But for at least a year or two they'll keep this iron as a Star exclusive. Len Johnson has given me an exclusive deal for US retail of this item and is taking a very, very small margin on it. So, thanks to circumstances we can offer this iron at $190. Delivery will be in December.