Fluorocarbons waxes are a skier’s best friend

Wax Room

Tue, Feb 22, 2011 - By Swix

Fluorocarbons waxes are a skier’s best friend. These miracle lubricants gain their qualities from extremely negatively charged Fluorine atoms that repel the also negatively charged Oxygen in H2O (and also commonly negatively charged dirt.) FC’s decrease the surface tension and surface area of water and effectively turn the high suction water layer between the skis and the snow into slippery water ball bearings. The more H20 and Dirt present the more FC’s will increase ski speed.

Benefits of Fluorocarbon Enhanced Waxes and 100% Fluorocarbon Top Coats

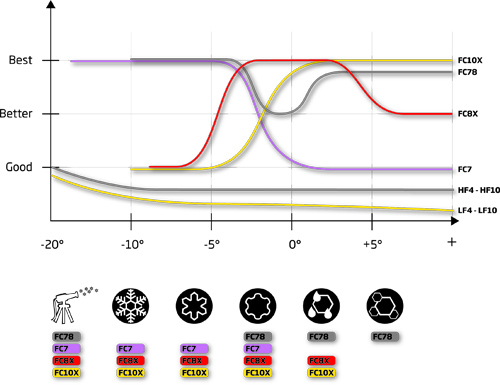

Your benefits will vary, and could easily be greater, based on numerous variables including snow type, humidity, ski condition, and application. Benefits also increase as length of race increases, humidity/water increases or dirt increases. It should be noted that in most every condition any FC Top Coat is better than using no FC Top Coat:

Table 1. Conservative Time Savings Corridors over 10km in common snow types.

| Hardness | FC | HF | LF | CH | |

| Very Wet +0C and Warmer |

10 | Fastest FC10X |

add 30 to 45+ secs |

add 45 to 65+ secs |

add 60 to 90+ secs |

| Normal Warm +1C to -4C |

8 | Fastest FC8X |

add 25 to 35+ secs |

add 30 to 45+ secs |

add 45 to 65+ secs |

| Normal Cold -2C to -8C |

7 | Fastest FC78 |

add 15 to 25+ secs |

add 20 to 35+ secs |

add 25 to 40+ secs |

| Cold -6C to -12C |

6 | Fastest FC78 |

add 5 to 15+ secs |

add 10 to 20+ secs |

add 15 to 25+ secs |

| Very Cold -10C and Colder |

4 | Fastest FC7 |

add 0 to 10+ secs |

add 5 to 10+ secs |

add 10 to 15+ secs |

In graphic form:

Figure 1. Swix CERA F speed comparison

Glide Waxes: Minimizing Dry and Wet Friction

The purpose of glide wax is to reduce the friction between ski and snow. This friction approaches pure dry friction at extremely cold temperatures and approaches pure wet friction at extremely warm temperatures but is always at some intricate and every changing combination of both dry and wet friction. The ideal wax compound for each snow condition must feature a perfect mixture or dry friction snow crystal penetration resistance properties and wet friction lubrication and moisture management qualities. Only the Cera Nova system provides A Perfect Wax for Each Snow Condition.

Hardness: 3, 4, 6, 7, 8, 10: From Dry Friction to Wet Friction

The most important aspect in a glide wax is its specific mixture of compounds to decrease Dry and Wet friction. Swix classifies this through its wax hardness classification 3-10. Number 3 waxes are Swix’s hardest and are engineered to minimize dry friction by shearing from the base when they meet sharp penetrating snow crystals. Number 10 waxes are the softest and engineered to minimize wet friction with the greatest moisture management and round snow crystal lubrication properties. Between these two extremes Swix petrochemical engineers have carefully crafted the ideal mixtures of hardness and moisture management/lubrication management capabilities for each temperature and snow condition.

Categories: CH, LF, HF, Cera F: Increased lubrication and speed

Swix’s Cera Nova waxes provide 4 Categories (CH, LF, HF/HFBW, Cera F) of waxes at most hardness levels with enhanced speed capabilities through the addition of specific advanced ingredients including dry lubricants, fluorocarbon compounds and 100% Fluorocarbon Top Coats.

- CH: 100% High Performance Hydrocarbon waxes are used as the building blocks of the Cera Nova matrix. They can be used as economical training and even racing waxes or as a base layer for Cera F. The coldest waxes use harder long chain synthetic hydrocarbons that perform very well alone in dry low humidity conditions and at warm temps the softer shorter chain paraffin waxes.

Fluorocarbon Enhanced Waxes: LF, HF

- Fluorocarbons (FC) are a skier’s best friend. These miracle lubricants gain their qualities from extremely negatively charged Fluorine atoms that repel the also negatively charged Oxygen in H2O (and also commonly negatively charged dirt.) FC’s decrease the surface tension and surface area of water and effectively turn the high suction water layer between the skis and the snow into slippery water ball bearings. The more H20 and Dirt present the more FC’s will increase ski speed.

- LF: These waxes have low-melt-point fluoro additives which enhance glide when compared to their CH building blocks. They can be used in racing with Cera F as a final layer or alone at low temps and low to medium humidity. They have lower Fluorine enhancement than the HF line.

- HF: These have a very high percentage of low-melt point fluorocarbon additives. With the increase in Fluorine atoms the wax increases both moisture management and dirt resistance. HF waxes are excellent when used alone, but ideal when used in combination with Cera F as an over layer. The more humidity, moisture, or dirt the more you want HF.

- HFBW: HF BlackWolf adds specific dry lubricants with great compression strength to resist penetration and low shear strength to make them slippery. These dry lubricants make BW the choice help when snow is dirty, coarse grained or abrasive man-made snow.

100% Fluorocarbon Top Coats

- Cera F: FC 100% Fluorocarbon wax over-layers are the finest of the miracle waxes and dramatically increase ski speed over Flourocarbon Enhanced let alone CH waxes in most all conditions. While in most any condition any FC is better than no FC, Cera F also comes in a complete range of hardness’s with the shortest softest chains best managing the moistest, roundest crystals and the longer harder chains managing colder harder but still high humidity crystals. But differences between FC’s vary less than differences between 4 and 10 in enhanced waxes. For best results FC’s must be applied to an under-layer of the appropriate hardness.